An inspection solution for

every production concept

In-line, stand alone or quick-response mobile

Any location, layout or deployment format

The INSPEKTO S70’s versatility, immediacy and deployment simplicity provide the ultimate flexibility to meet your present and future production models and QA needs.

The Inspekto solution provides multiple types of solutions and can be fitted in a variety of settings.

Integrated to the

production line

Installed on the production line, either End-of-The-Line or middle of the line, fully integrative to the PLC/Controller or MES/ERP systems

Multi-purpose

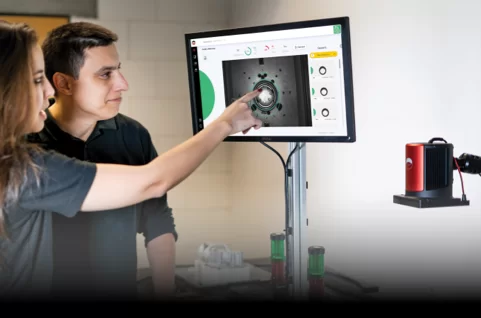

inspection station

A stand-alone inspection station to support multiple lines or manual handling, inspecting wide range of different products – from inspection of incoming goods, to final quality inspection of finished products

Mobile quick response

Immediately addressing urgent, or foreseen quality monitoring/quality assurance needs, the Inspekto system can be mobilized quickly from one spot to another with minor overhead and setup efforts