Mimics cognitive

human vision for

quality inspection

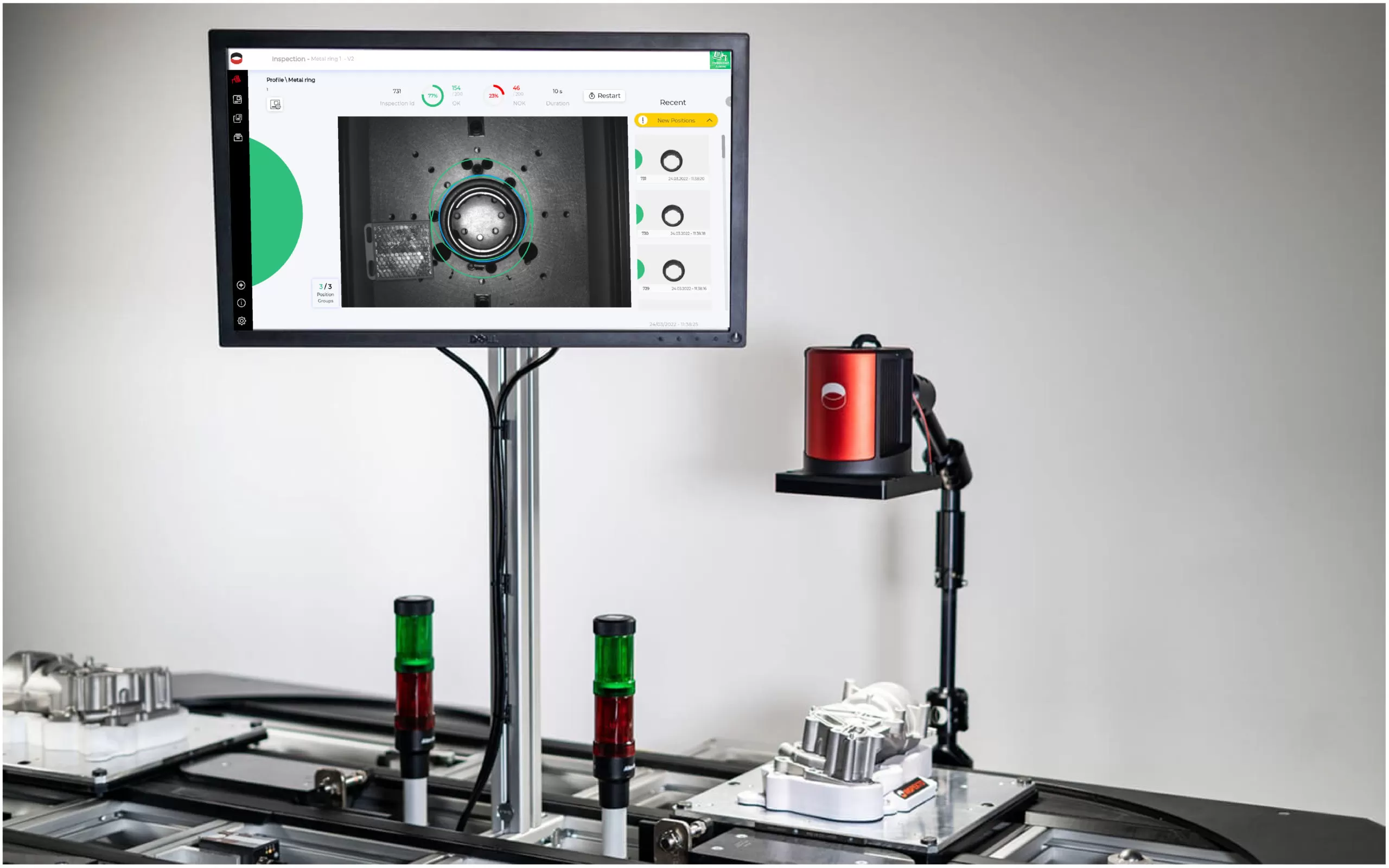

3 Synergetic AI Engines Driving Unique Electro-Optics

The best of both worlds: Human cognition coupled with machine repeatability and accuracy

AMV-AI – a novel holistic machine vision technology

Whenever you look at something, your brain carries out a series of processes without you even acknowledging it. First,

it controls the eyes in order to acquire the best image then it recognises what is the particular object seen.

Then, it inspects anomalies to reach an OK/NOK decision.

Autonomous Machine Vision – Artificial Intelligence (AMV-AI) follows this same cognitive process. AMV-AI comprises of three

independent and synergetic AI engines driving a unique electro-optic system

Getting the Image

- Self set-up of all optics parameters per specific use case & scenario

- Self adjust mechanism during runtime dynamically mitigating changes in the production environment

- Smartly selects optimized image from the live stream for the recognition and inspection engines

Identifying the Part

- Recognizes and detects rigid objects of any shape and surface

- One reference image is sufficient for detection

- Supports variations in location and rotation in the Field of View (FOV)

- Can be self-triggered or use an external trigger

Finding the Defect

- Requires 20-30 good parts (OK) only, with no onsite training

- Understands product tolerances

- Physical attributes

- Differentiate between defects and permittable defects (without any prior defect references nor training)

- Ongoing improvement via continuous deep- learning

Fully Contained Electro-Optic System

- A multi parameter electro-optic vision system designed for ultimate flexibility

- Embedded smart PWM lighting array with varying light direction and intensities

- Mega pixel global shutter image sensor with optical zoom

- Novel, patent-pending architecture

AMV-AI more than just machine vision AI

Enabling out-of-the-box deployment-ready solution, not just a software component

Powering all phases of the machine vision process, not just the inspection decision

End to end: from image capture through part recognition to defect detection

Dynamically adjusts the electro optics system to acquire the best image (from one sample)

Automatic independent recognition of the object

Small amount of OK images. Specific defect sensitivity increase option

No on-site training process, no expert required, requires low amount of data

Autonomous performance optimization by active recommendations engine

vision with AI

Defect inspection only

Image acquisition is pre-set and not dynamic

External trigger

Requires many OK & NOK samples for each defect type

Complex, expert dependent on-site/cloud AI training, requires rule-based programming for full solution pattern matching

Periodical, reactive expert dependent complex maintenance with re-training

AI-driven optimization to mitigate

changes in production

The unique AMV-AI technology adapts to the changes in your production line and to your Use Case

- Unique dynamic algorithm module offers active recommendations for fine tuning the quality inspection

- Learns your inspection requirements, offering performance optimizing AI-based recommendations for continuous quality inspection

- Recommendations ensure stable quality performance in an ever-changing production environment

- Capable of selectively boosting the inspection sensitivity to a specific defect type, while maintaining general sensitivity to other types of defects

Integrated optics and

lighting optimization

- Embedded illumination is controlled by pulse-width modulation

- Using boosted pulses of illumination synchronized with the camera exposures, taken autonomously at the best moment to capture the image without creating discomfort to nearby workers

- Novel LED arrangement and control allow directional and intensity varying lighting per image. Multiple images are then fused to create a single reflection-less HDR image

- Unique technology to eliminate self reflection as well as reflections from external illumination source for both stationary and moving parts

- No flickering or noticeable light variation to ensure nearby employee comfort and safety

- Real time, dynamic adjustments to the the full set of the electro-optics parameters

Defect detection, without

defect definition

The AI engine knows the characteristics of a good part and can deduct a defect part based on this. There is no need for any bad parts during learning.

- No need for not OK (NOK) or defected samples or images

- No need to create defect definition rules

- Accurate identification of the smallest defects

- High sensitivity to identify defects vs. permittable variations

- Industrial grade inspection performance with very few good samples required

- Picks small defects that would be missed by the human eye.

- Identifies defects on black surfaces.

- Inspects deep and complex 3D shapes.

- Easily inspects and makes decisions for complex sequence scenarios with multiple inspection points

Sophisticated AI based on intense research

Our super skilled research team has been working on meta-learning since 2015, when the academic world just started in 2019.

AMV-AI is a novel AI architecture and a unique formulation of neural networks utilising computer vision, deep learning and real-time software optimization technologies.

million images

different objects

vision & deep learning expertise

Interested?

Contact our experts for a free online demo