Blog

THREE WAYS AUTONOMOUS MACHINE VISION (AMV) BENEFITS PLASTIC INJECTION MOULDING

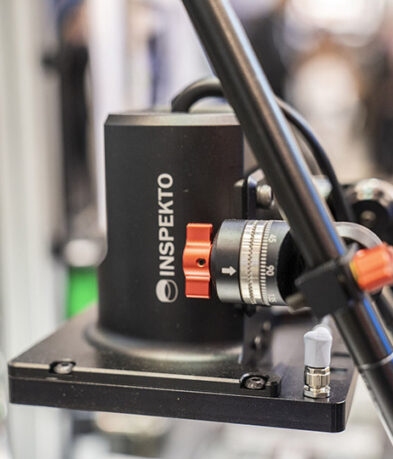

Autonomous Machine Vision is a new approach to quality assurance (QA) developed by Inspekto, a German company with Israeli DNA. As the name suggests, this technology is conceived to be autonomous in every way, from determining the ideal number of samples the system needs to learn the characteristics of the item, to self-adjusting the camera settings to obtain the best image possible of the item to be inspected.

CAMERA SPECS – NOT THE FRONTIER IN THE ERA OF AI

Autonomous Machine Vision (AMV) offers a new approach to visual QA. If humans had the eyesight of an eagle, we could spot an ant from the top of…

APPLICATIONS FOR PRODUCTIVITY ENHANCEMENT

Traditionally, plastic injection moulding is a difficult application for machine vision. The highly reflective surface of plastics is hard to illuminate correctly, and the fact that the same production line can create items of different colours and shapes is problematic for traditional solutions, only capable of inspecting one product at a time.

TRACING QA THROUGH TIERS

Improving quality in the automotive supply chain. Each year, approximately a million vehicles are recalled in the UK for safety repairs. In the USA, 23 per cent of…

HOW AUTONOMOUS MACHINE VISION CAN HELP WARD OFF THE LOOMING RECESSION

The Great Depression that hit the US in the 1930s was probably the worst economic recession ever registered. To guide the country out of it, President Roosevelt launched a series…

“The advance of technology is based on making it fit in so that you don't really even notice it, so it's part of everyday life.”

Bill Gates, Co-founder of Microsoft

IT’S TIME TO DEMOCRATISE QUALITY ASSURANCE

Traditionally, plastic injection moulding is a difficult application for machine vision. The highly reflective surface of plastics is hard to illuminate correctly, and the fact that the same production line can create items of different colours and shapes is problematic for traditional solutions, only capable of inspecting one product at a time.