Inspekto presents Autonomous Machine Vision at the Motek show

August 15, 2021

Autonomous Machine Vision AI is the last critical component for complete automation systems

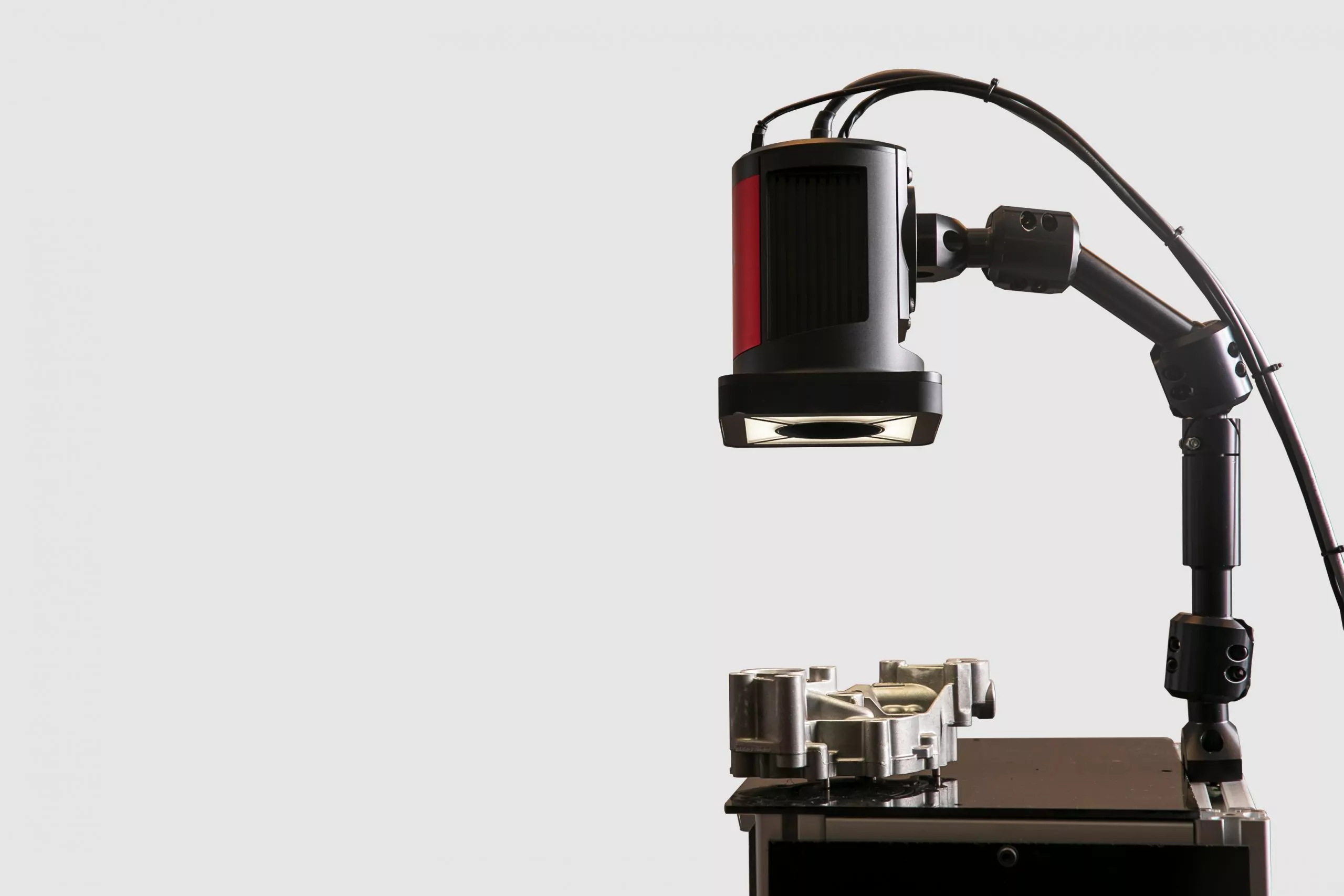

Inspekto, global pioneer of Autonomous Machine Vision (AMV), will present its AMV system INSPEKTO S70 Gen.2 for industrial quality inspection during the Motek trade fair from October 5th to 8th, 2021 in Stuttgart. The recently introduced second generation of this system enables reliable quality checks in numerous applications. Based on artificial intelligence and easy to set up and deploy, the system creates the conditions for end-to-end automation.

The international trade fair Motek is the world’s leading event in the areas of production and assembly automation, feeding technology and material flow, rationalization through handling technology and industrial handling. After the pandemic-related cancellation in 2020, it will take place again this year from October 5 to 8, 2021 in Stuttgart. At Motek, trade show visitors will experience cross-divisional solutions for the entire world of automation and can find out more about the INSPEKTO S70 Gen.2 machine vision system at Inspekto’s booth 7/7216. Thanks to the unique approach of Autonomous Machine Vision AI, this system enables end-to-end automation of many production processes and thus paves the way to Industry 4.0. The INSPEKTO S70 Gen.2 enables high-quality inspection of objects of all kinds and, unlike conventional machine vision solutions, can be installed within a very short time by users who do not have any knowledge of machine vision or AI.

The reason for this is the further development of Inspekto´s Autonomous Machine Vision Artificial Intelligence (AMV-AI™). Essential elements of this machine vision system are three modules based on artificial intelligence, which ensure the dynamic adjustment of the operating parameters of the image recording system to the respective image processing task in real time, take over the identification, classification and 3D alignment of an object within the recorded image and the actual inspection of objects.

Unlike traditional machine vision solutions, the INSPEKTO S70 Gen.2 is extremely simple to set up. Users only need an average of 20 to 30 good sample parts and can immediately create feasibility studies for assignments in a wide variety of applications. The system’s unique advantage is that it’s pre-trained, dramatically shortening the time needed for set up and for the initiation of image processing.

For small and medium-sized companies as well as for system integrators of automation systems, INSPEKTO S70 Gen.2 offers an invaluable advantage over traditional machine vision systems. The simple handling and installation no longer requires vision experts and can be done in a significantly shorter amount of time, which extremely increases cost-effectiveness. In this way, users can gain control of their quality assurance process end-to-end, improving levels of production verification.

Inspekto is an international industrial company whose development team has accumulated decades of experience in the areas of machine vision, AI research and industrial solutions. The company, with a development centre in Israel, builds on a strong presence in Germany, where the European headquarters are located with a modern demo centre. There, users have the opportunity to have their components individually checked by competent experts in order to quickly find effective solutions. Since earlier this year, Inspekto is led by global CEO Bernd Schumacher, who is based in Germany and is a long-standing international business manager in the high-tech sector.

“Machine vision is an important component for the complete automation of many production processes, “emphasises Schumacher. “Due to its complexity, this technology was previously often only available to large companies that had access to the necessary internal know-how and capex. INSPEKTO S70 Gen.2 now also enables small and medium-sized companies as well as system integrators in many industries to implement cost-effective solutions based on an easy-to-use, flexible and powerful machine vision system and thus improves their profitability. The value proposition in terms of higher yield and customer satisfaction that our customers can now enjoy is at the heart of our technological breakthrough.”